Le olive raccolte nell’arco della giornata dagli agricoltori della zona vengono conferite al frantoio in bins arieggiati. Una volta arrivate in frantoio le olive vengono pesate per poi essere immediatamente defogliate e lavate con appositi macchinari; in questo consiste la prima fase di lavorazione. La seconda fase inizia con la molitura mediante quattro molazze in pietra per la durata di circa venti minuti.

Le olive raccolte nell’arco della giornata dagli agricoltori della zona vengono conferite al frantoio in bins arieggiati. Una volta arrivate in frantoio le olive vengono pesate per poi essere immediatamente defogliate e lavate con appositi macchinari; in questo consiste la prima fase di lavorazione. La seconda fase inizia con la molitura mediante quattro molazze in pietra per la durata di circa venti minuti.

Subito dopo inizia la fase di gramolazione in cui la pasta viene messa in condizioni ottimali per subire il processo di centrifugazione sotto temperatura controllata di 27 °C. In questa fase viene separata la parte solida da quella liquida, l’acqua di vegetazione e l’olio vengono mandati al processo finale, mentre la sansa viene stoccata all’esterno del frantoio.

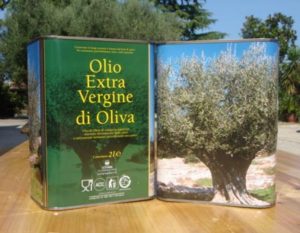

Arriviamo così al processo finale in cui l’olio viene separato dall’acqua di vegetazione mediante centrifugazione. Da qui l’olio viene stoccato in recipienti in acciaio inox presso magazzini a temperatura controllata. Successivamente oltre alla vendita all’ingrosso, l’olio viene filtrato e confezionato in bottiglie da 750 ml e lattine da 1 litri, 2 litri e 5 litri.

Si effettuano forniture per ristoranti.